Leading Pharmaceutical Packaging Manufacturer

Delivering cutting-edge flexible and paper box packaging solutions for healthcare, pharmaceuticals, and other industries.

Innovative Packaging Solutions

Customized Printing

BRC and ISO Quality Certification

Complete Service

Pharmaceutical Packaging Solutions Tailored to Your Needs

We manufacture pharmaceutical flexible packaging and paper box packaging, offering high-quality, customized solutions for the global pharmaceutical industry. Our products comply with ISO Certified and FDA standards, ensuring safety and quality.

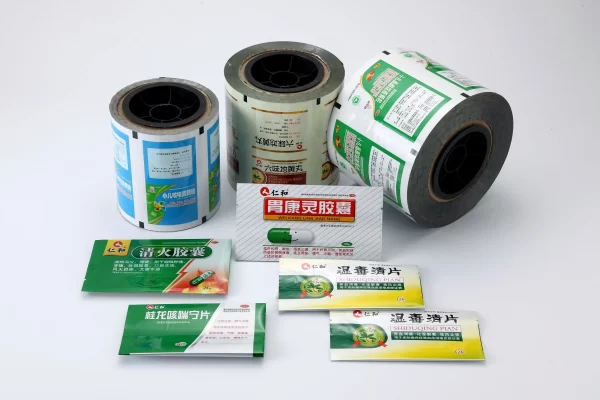

Pharmaceutical Packaging

Pharmaceutical grade, high barrier, moisture and oxidation resistant, ensure the safety of medicines.

Healthcare Packaging

Eco-friendly and durable, leak-proof and moisture-proof, safe protection for a wide range of healthcare products.

Food Packaging

High-barrier, moisture-proof, ensure freshness, environmentally friendly option.

Daily Chemical Packaging

Corrosion-resistant, leak-proof, secure sealing, compatible with a wide range of liquids and pastes.

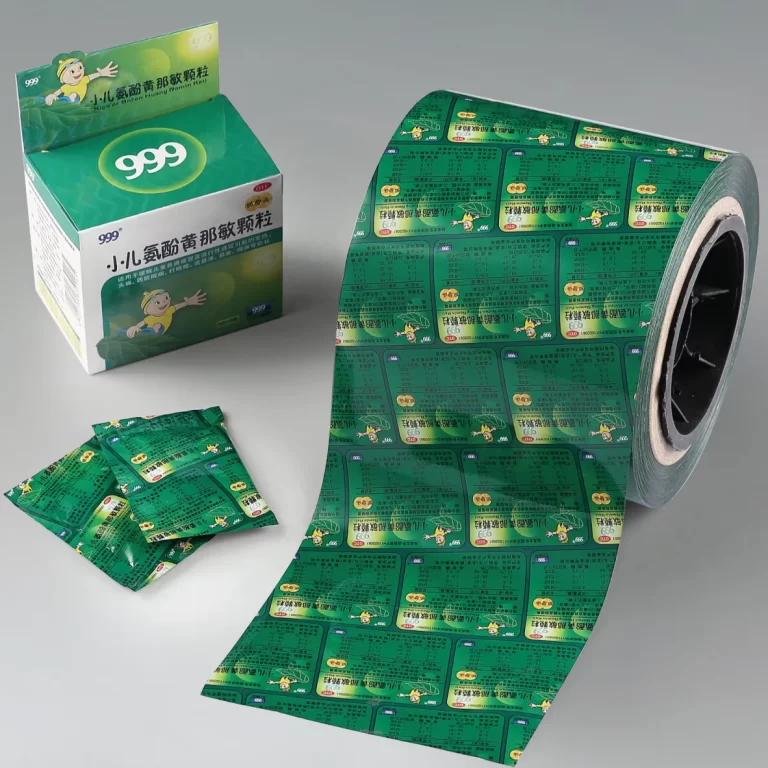

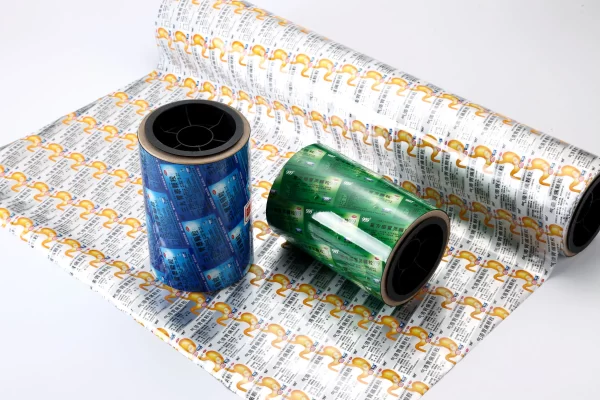

Custom Pharmaceutical Packaging By Different Types

As a professional pharmaceutical packaging manufacturer, we specialize in high quality packaging from flexible packaging to paper box packaging solutions to meet different needs and ensure product safety and sustainability.

Extensive Custom Pharmaceutical Packaging Options

Meet all your specific needs with our flexible customization services. Whether it's packaging design, sizing, or material selection, we can create the perfect pharmaceutical packaging solution for your needs.

Material Selection

Flexible Packaging: PE, PET, nylon, aluminum foil, etc., providing properties such as high barrier, puncture resistance.

Paper packaging: white cardboard, kraft paper, corrugated paper, etc., to meet the requirements of environmental protection or texture.

Paper packaging: white cardboard, kraft paper, corrugated paper, etc., to meet the requirements of environmental protection or texture.

Size and Shape

Flexible Packaging: flexible and customized bag types, such as stand-up pouches, zipper bags, three-side sealed bags.

Paper Packaging: customized design, common such as sky and earth cover, folding carton, etc.

Paper Packaging: customized design, common such as sky and earth cover, folding carton, etc.

Printing Design

Flexible Packaging: support color printing, common gravure and flexographic printing, the surface can be dealt with matte or glossy.

Paper Packaging: can be laminated, hot stamping or UV printing, to enhance the visual effect of packaging.

Paper Packaging: can be laminated, hot stamping or UV printing, to enhance the visual effect of packaging.

Functionality

Flexible Packaging: provide moisture-proof, anti-oxidation, UV protection, can be added easy to tear and zipper closure.

Paper Packaging: environmentally friendly, recyclable or degradable, can also be added to the oil, waterproof coating.

Paper Packaging: environmentally friendly, recyclable or degradable, can also be added to the oil, waterproof coating.

About Meishida

Trusted Pharmaceutical Packaging Manufacturer in China

GUANGDONG MEISHIDA MEDICINE PACKAGING MATERIALS CO., LTD. is a high-tech enterprise specializing in the production of medicine packaging materials. Listed on NEEQ in 2016 (stock code: 837877), the company is a key player in the pharmaceutical packaging industry, recognized as a vice-chairman member of Guangdong Medicine Packaging Material Committee.

With over 25,000 square meters of modern facilities, including advanced 100,000-grade purification workshops and 10,000-grade laboratories, Meishida is equipped with state-of-the-art production and testing equipment. The company holds ISO9001:2015 and ISO14001:2015 certifications and has strategic partnerships with over 40 well-known pharmaceutical enterprises.

0+

Years of Experience0+ m²

Floor Space0

Purification Workshop0+

Cooperation with Pharmaceutical CompaniesOur Advantages

Leverage Our Expertise. With state-of-the-art manufacturing and a dedicated R&D team, we bring your packaging to life with precision and quality.

Modern Production Facilities

Over 25,000 square meters of plant with advanced automated equipment to ensure efficient and stable production of pharmaceutical packaging.

View Our Production Technology ➔

Strict Quality Control

Class 100,000 purification workshop and Class 10,000 laboratory, comprehensive quality control, in line with ISO9001 and ISO14001 standards.

View Our Quality Control ➔

R&D Capability

Specializing in new materials and technological innovation, we own a number of patents and have introduced high-barrier and Eco-friendly pharma packaging materials.

Qualifications and Patents ➔

01

Flexible Packaging Workshop

The flexible packaging workshop is equipped with fully automated production lines, focusing on the efficient manufacturing of environmentally friendly materials to ensure the high barrier performance and environmental protection characteristics of each product.

Explore Our Clean Room02

Paper Packaging Workshop

The paper packaging workshop is equipped with the latest technology to ensure that the production process is efficient and precise to meet all kinds of customized needs, while focusing on environmental protection and sustainable development.

Learn About Our Advanced Equipments03

Laboratory

The laboratory adopts a 10,000-class clean environment and advanced testing equipment to strictly control every step to ensure that the products meet international standards.

Research & Development StrengthsTrusted by Industry Leaders

We work with many of the world's leading pharmaceutical companies to provide high quality packaging solutions. We proudly supply pharmaceutical flexible and paper packaging to customers in over 40 countries worldwide.

Certification

Meishida strictly follows GMP, ISO13485, and other international standards, with full-process aseptic control to ensure product safety and compliance, providing high barrier protection solutions for pharmaceuticals, vaccines, and medical consumables.

Sustainable Pharmaceutical Packaging Solutions

Sustainable Packaging for a Greener Future. Our commitment to eco-friendly materials and processes ensures minimal environmental impact.

Learn About Our Sustainability CommitmentBlogs and News

Follow our blog for the latest industry trends, packaging innovations and company news.

What is Rollstock Packaging? A Complete Guide for the Pharmaceutical Industry

In the field of pharmaceutical flexible packaging, Rollstock packaging has become one of the key...

Read More →

What is Flexible Packaging? Explore New Trends in Pharmaceutical Packaging

Packaging in the present drug industry is not only just a case of "wrapping" products,...

Read More →

5 Benefits of Custom Pharmaceutical Packaging for Brands

In the pharmaceutical industry, packaging is not only a protection for drugs but also an...

Read More →Contact Us for Your Needs

We're happy to help!

Not sure what you need? Contact our packaging experts who will help you find the best custom pharmaceutical packaging solutions for your brand.

+86-13827303202[email protected]Wenli Industrial Zone of Chaoshan road Anbu,Chaoan District, Chaozhou city, Guangdong Province