Custom Pharma Packaging Solutions

Safety and product integrity remain the paramount priorities in pharmaceutical packaging design. Our custom pharma packaging solutions combine robust construction with precision engineering to ensure optimal drug protection throughout the supply chain. Discuss your needs with our packaging experts today!

Your Trusted Partner for Custom Pharma Packaging

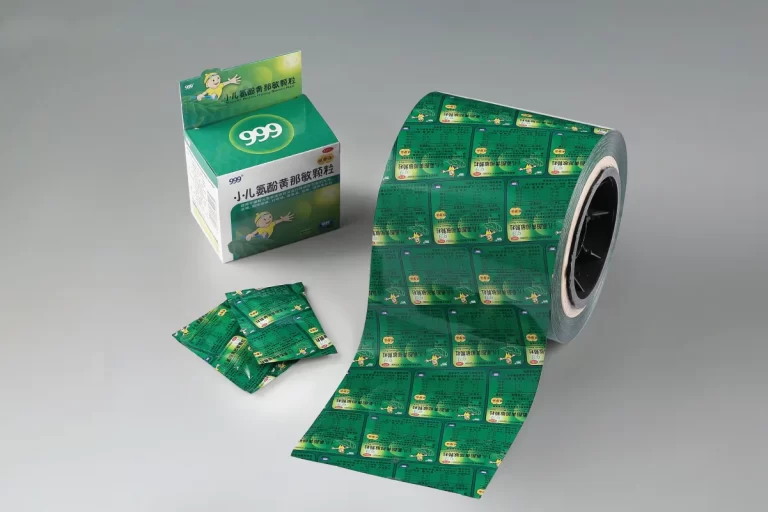

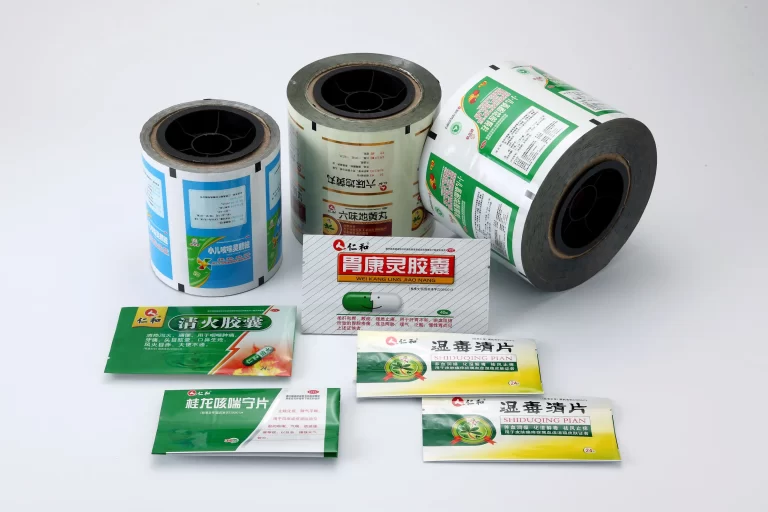

Meishida, a leading pharmaceutical packaging manufacturer, provides custom solutions for the pharmaceutical, medical, and nutraceutical industries. Our product range includes blister packs, pouch packs, and roll stock packs, all produced with advanced technology to ensure safe and aseptic packaging.

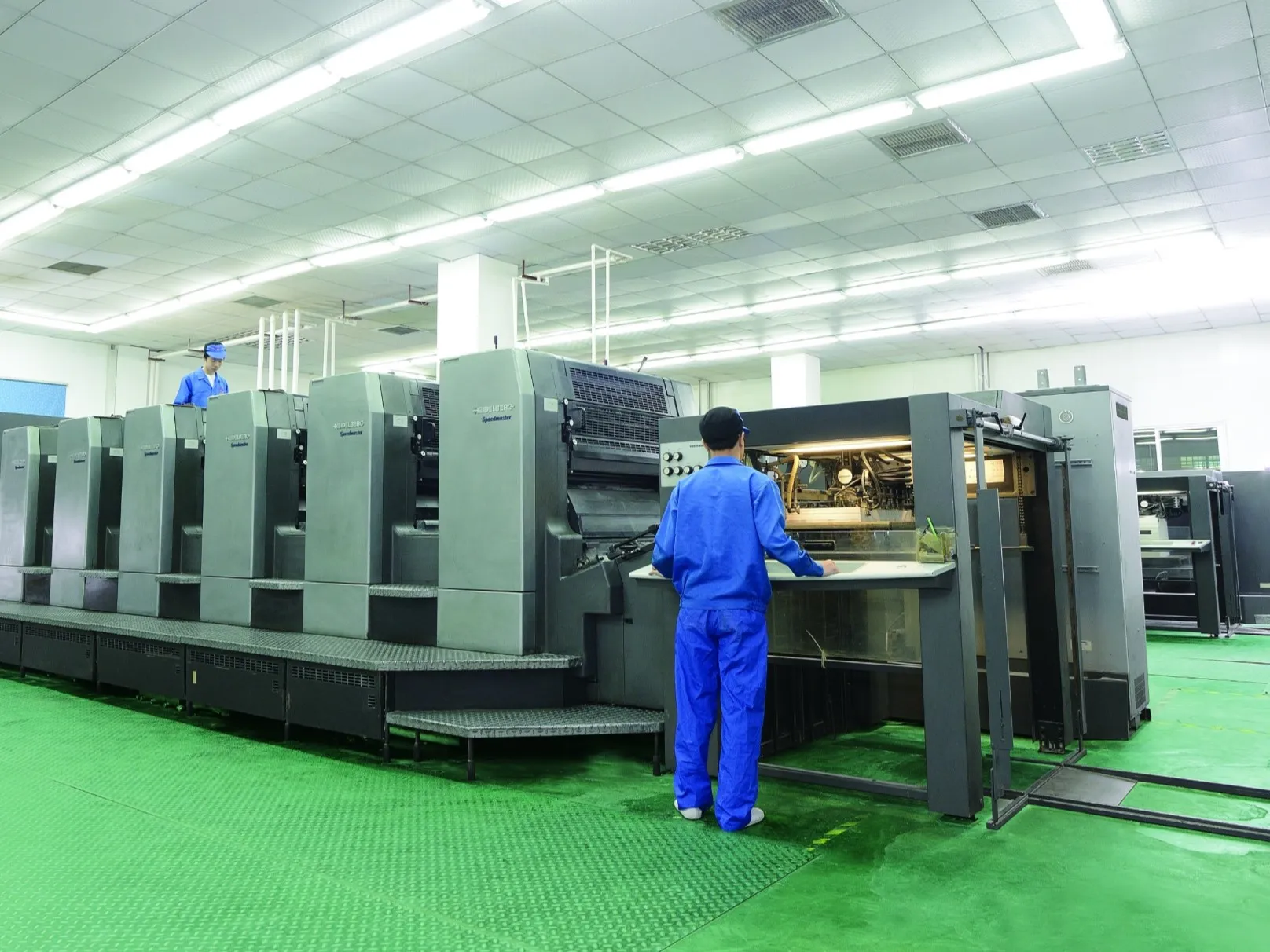

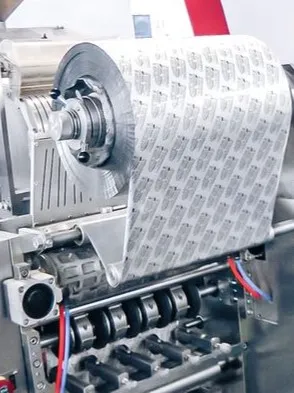

With over 25,000 sqm of modern facilities, including 100,000-grade purification workshops and 10,000-grade laboratories, we are equipped with state-of-the-art production and testing equipment. We are ISO9001:2015 and ISO14001:2015 certified, ensuring high-quality and environmentally friendly packaging.

Committed to innovation and quality, we continuously upgrade our technology to meet market demands, making us a trusted partner for pharmaceutical and medical companies.

With over 25,000 sqm of modern facilities, including 100,000-grade purification workshops and 10,000-grade laboratories, we are equipped with state-of-the-art production and testing equipment. We are ISO9001:2015 and ISO14001:2015 certified, ensuring high-quality and environmentally friendly packaging.

Committed to innovation and quality, we continuously upgrade our technology to meet market demands, making us a trusted partner for pharmaceutical and medical companies.

Tailor-made Pharma Packaging Types for Your Brands

At Meishida Pharma, we specialize in providing customized medicinal packaging solutions that align with your brand's unique needs. Whether it's primary packaging like flexible films and pouches, or secondary packaging for safe transport and branding, we deliver high-quality, compliant, and cost-effective packaging solutions. Trust us to safeguard your products while enhancing their presentation and market appeal.

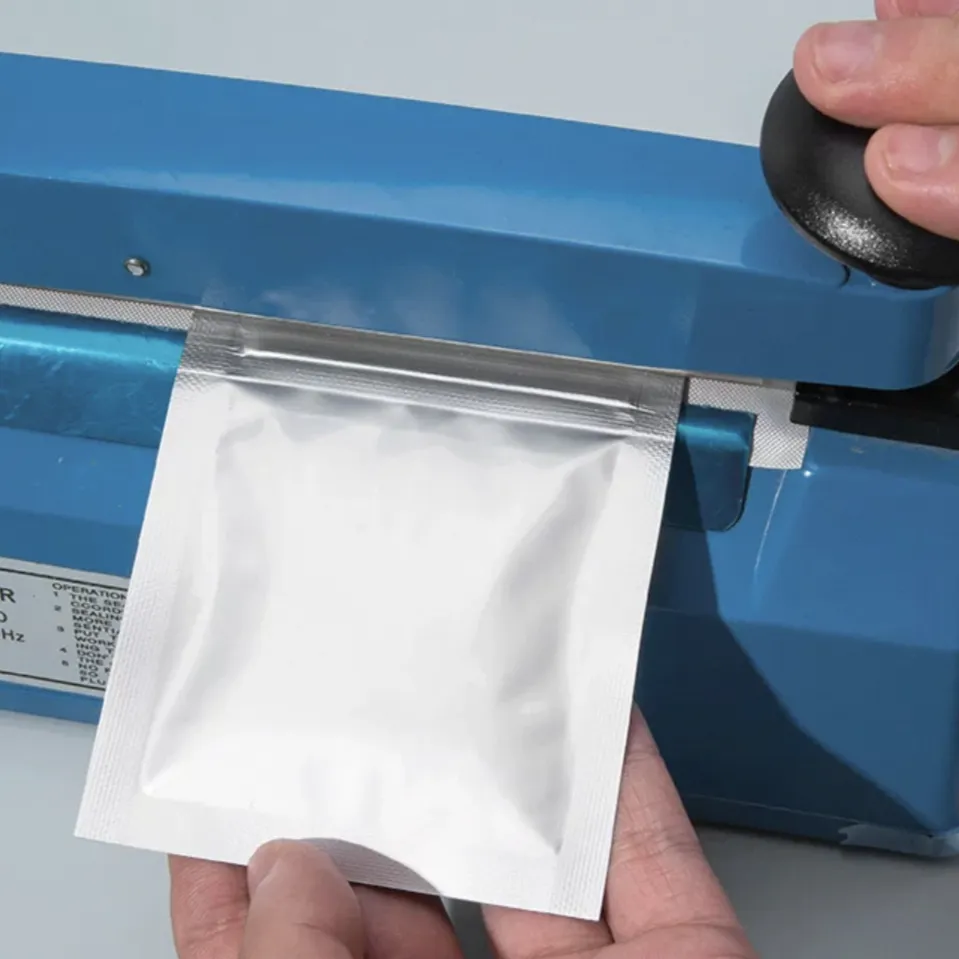

Custom Primary Packaging

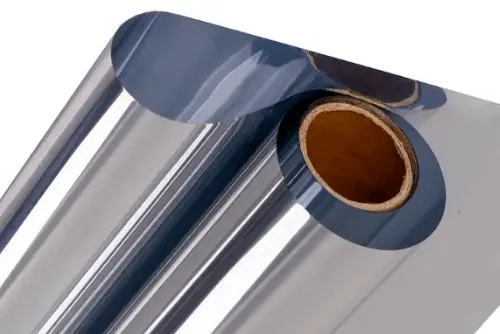

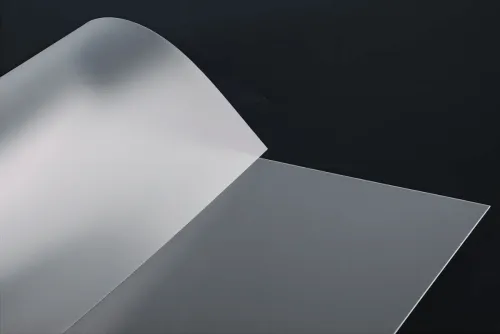

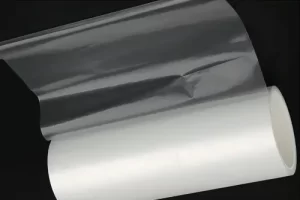

Meishida offers customized primary packaging solutions designed to protect and preserve your medical products. Whether it's flexible film, pouches or specialized packaging, we ensure optimal safety, compliance and durability.

Our primary packaging can be tailored to your specific product needs, ensuring top-notch protection and compliance with international standards.

Our primary packaging can be tailored to your specific product needs, ensuring top-notch protection and compliance with international standards.

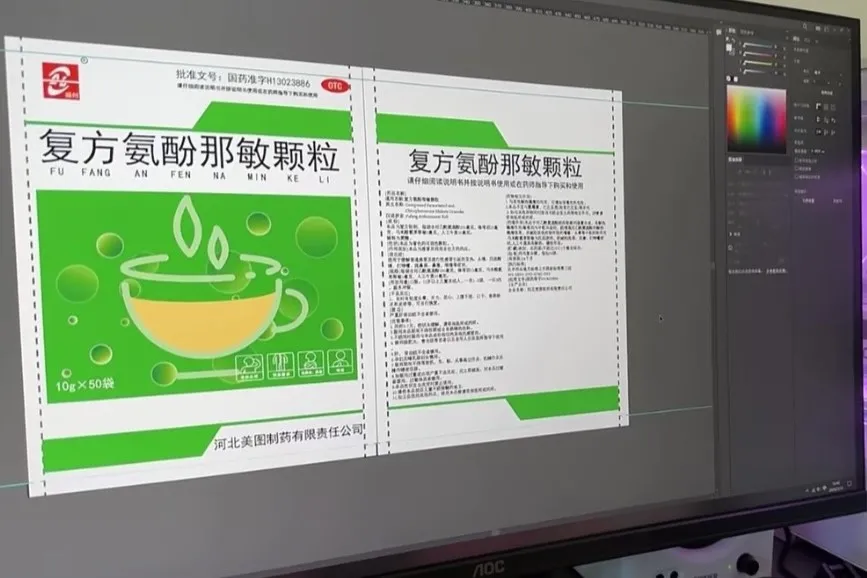

Custom Secondary Packaging

Custom pharma secondary packaging solutions including branded pharma boxes, cartons or blister packs provide strong protection and ensure your packaging stands out on pharmacy shelves and provides effective messaging.

Meishida's specialized pharma packaging solutions optimize shipping and storage efficiencies, and can also help you reduce costs and increase visibility.

Meishida's specialized pharma packaging solutions optimize shipping and storage efficiencies, and can also help you reduce costs and increase visibility.

Expertly Crafted Packaging Solutions for the Pharmaceutical Industry

Custom Pharma Flexible Packaging Solutions

Whether it's a wide range of high-barrier materials, pouch designs (e.g., back-seal pouches, triple-seal pouches, etc.), high-definition printing, additional features (easy-tear closure, child-resistant, etc.), or flexible specifications, we ensure drug safety, extend shelf life, and enhance brand image.

Aluminum Foil

Aluminum Foil Biodegradable Film

Biodegradable Film Bopp Film

Bopp Film Nylon Film

Nylon Film Paper Laminate

Paper Laminate PE Film

PE Film Pet Film

Pet Film PP Film

PP Film Back Seal Organ Bag

Back Seal Organ Bag Back Seal Pouch

Back Seal Pouch Eight Side Seal Pouch

Eight Side Seal Pouch Eight Side Seal Zipper Pouch

Eight Side Seal Zipper Pouch Quad Seal Pouch

Quad Seal Pouch Roll Film

Roll Film Shaped Pouch

Shaped Pouch Side Seal Bag

Side Seal Bag Stand Up Pouch

Stand Up Pouch Stand Up Zipper Pouch

Stand Up Zipper Pouch Three Side Seal Pouch

Three Side Seal Pouch Zipper Bag

Zipper Bag Cold Seal

Cold Seal Easy-tear Opening

Easy-tear Opening Heat Sealing

Heat Sealing Zipper Seal

Zipper Seal

Avoid Light

Avoid Light Easy-tear

Easy-tear Custom Size

Custom Size Waterproof and Dustproof

Waterproof and DustproofCustom Pharmaceutical Boxes Packaging Solutions

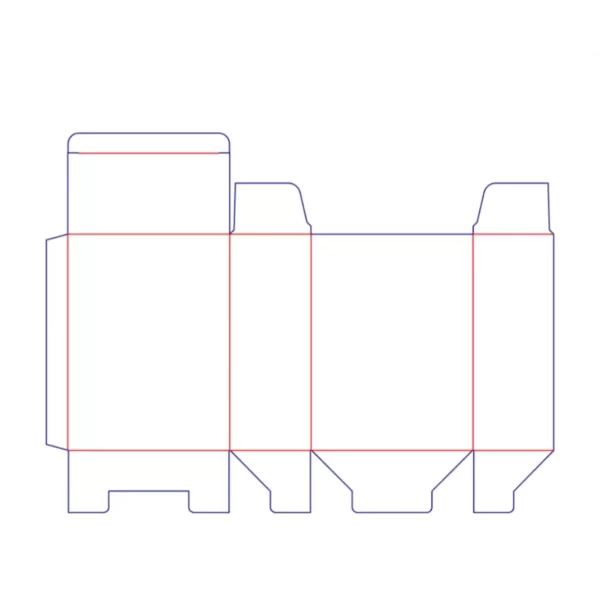

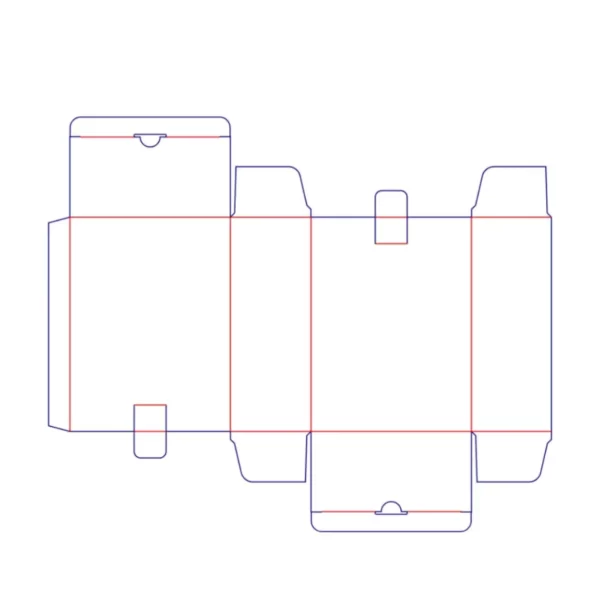

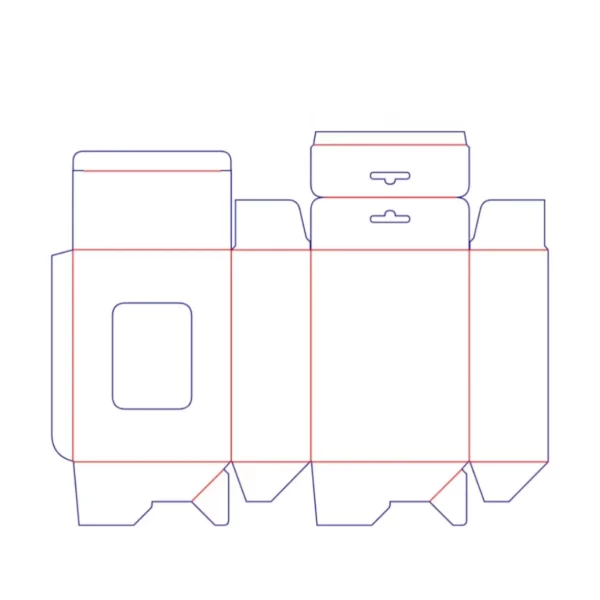

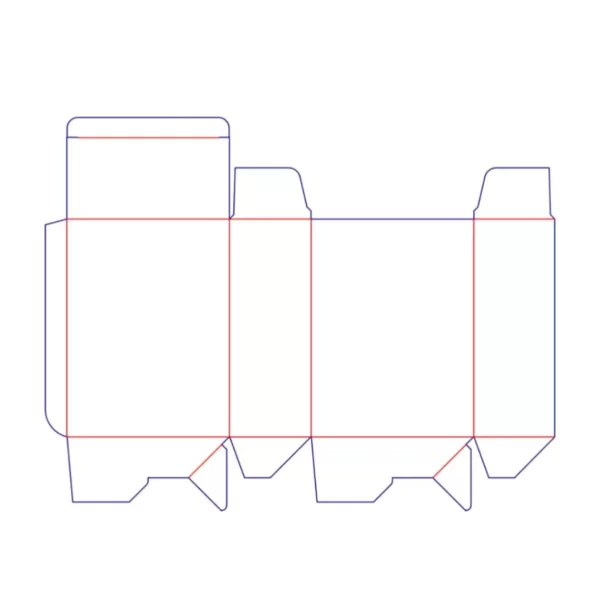

Whether it's a variety of box designs, environmentally friendly material selection, structural optimization, personalized printing and technology, functional integration (anti-counterfeiting, moisture-proof, etc.) and precise size customization, we meet the needs of pharmaceutical products for display, storage and transportation, while taking into account the practicality and brand recognition.

Coated Paper

Coated Paper Corrugated Paper

Corrugated Paper Double Grey Board

Double Grey Board Grey Back White Board

Grey Back White Board Kraft Paper

Kraft Paper Self-adhesive Label

Self-adhesive Label White Cardboard

White Cardboard Die Cutting

Die Cutting Double Glue Paper

Double Glue Paper Embossing

Embossing Edge Coating

Edge Coating Foaming

Foaming Hot Stamping

Hot Stamping Lamination

Lamination Laser Cutting

Laser Cutting Leather Stamping

Leather Stamping Matte Finish

Matte Finish Oil Coating

Oil Coating Pressing

Pressing UV Coating

UV Coating Variable QR Code

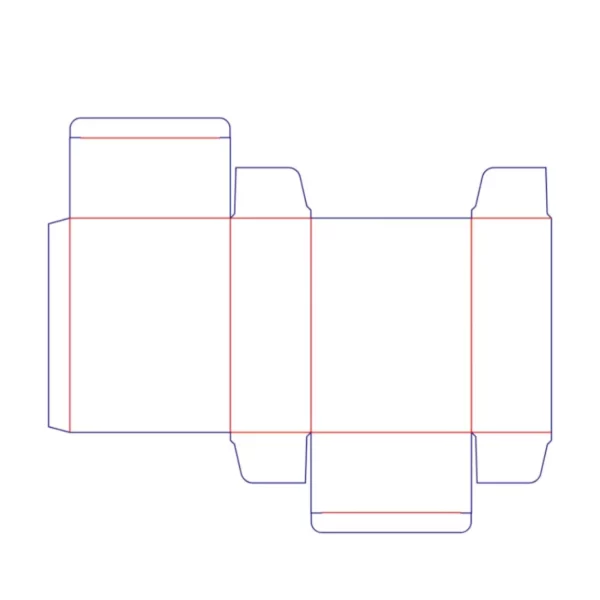

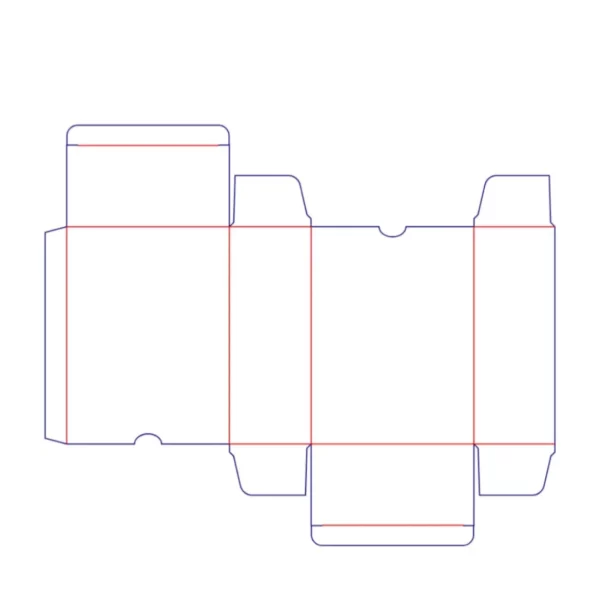

Variable QR Code Bottom Lock Box

Bottom Lock Box Finger Lock Reverse Insert Lock Box

Finger Lock Reverse Insert Lock Box Lock Tab Reverse Insert Lock Box

Lock Tab Reverse Insert Lock Box Reverse Insert Lock Box

Reverse Insert Lock Box Self-locking Bottom Box with Window and Hook

Self-locking Bottom Box with Window and Hook Self-locking Bottom Box

Self-locking Bottom BoxCustom Pharma Packaging Process

1.Demand Communication and Analysis

Through telephone, email or video conference, we will deeply understand your pharmaceutical characteristics, packaging needs and brand positioning, and provide professional design consultation and advice.

2.Design and Quotation

Based on your needs, we will customize the drug packaging design scheme, covering details such as material, structure, printing, etc., and provide a transparent and detailed quotation for mass production.

3.Sample Production and Optimization

Rapidly produce samples to ensure that the packaging meets pharmaceutical protection, brand presentation and regulatory requirements. Optimize the design based on feedback until it fully meets your expectations.

4.Mass Production and Efficient Delivery

After sample confirmation, mass production is initiated. We strictly follow pharmaceutical packaging standards and control every step of the process to ensure that high-quality packaging is delivered on time, contributing to your drug safety and market success.

High-standard Pharmaceutical Packaging, Protecting Safety, Empowering Brands

Contact us today for a competitive price quote for custom pharma packaging.

FAQs About Common Custom Pharma Packaging

1. What is Flexible Packaging for Pharmaceuticals?

Flexible packaging for pharmaceuticals refers to the form of packaging made of flexible materials (e.g. film, aluminum foil, etc.), and the common types include pouches, rolls, and so on. It has the advantages of lightweight, moisture, oxidation, and extend the shelf life of drugs, widely used in tablets, capsules, granules and other pharmaceutical packaging.2. What Types of Medicine are Flexible Packaging Suitable for?

Flexible packaging is suitable for a variety of drug types, including tablets, capsules, granules, powders and so on. It can be used for the packaging of OTC drugs, prescription drugs, healthcare products and medical devices to meet the storage and transportation needs of different drugs.3. What are the Material Options for Customized Flexible Packaging?

We offer a wide range of high barrier materials, such as aluminum foil, laminated film, PE film and so on. These materials are moisture-proof, oxidation-proof, heat-resistant, environmentally friendly, etc. The most suitable combination of materials can be selected according to the characteristics of the drugs.4. How to Ensure Flexible Packaging Meets Drug Safety Standards?

We strictly follow GMP standards and pharmaceutical packaging regulations, and use food-grade safety materials to ensure that the packaging is non-toxic and non-polluting. At the same time, the packaging is designed to be moisture-proof, oxidation-proof, and light-proof to ensure drug safety and stability.5. What Customized Design Options are Supported?

We support a variety of customization options, including pouch type (such as back-seal pouches, stand-up pouches, three-side-seal pouches), printing (brand logos, drug information, anti-counterfeit logos), functionality (easy-tear closure, zippers, child-resistant opening) and so on, to meet your personalized needs.6. How Long is the Production Cycle for Customized Flexible Packaging?

It usually takes 5-7 working days from design to sample confirmation, and the mass production cycle depends on the order quantity, usually 2-4 weeks. The specific time will be adjusted according to the design complexity and order size.7. What is the Minimum Order Quantity?

Our minimum order quantity is usually 10,000 pieces, but we also support small quantity customization, which can be negotiated according to customers’ requirements.8. How to Ensure the Sealing and Durability of Packaging?

We use advanced heat sealing and ultrasonic sealing technology to ensure the sealing of the package. Meanwhile, we test the pressure resistance, tear resistance and durability of the packaging through strict quality control processes to ensure its reliability in transportation and storage.9. Do You Support Environmentally Friendly Material Options?

Yes, we offer environmentally friendly material options, such as biodegradable films and renewable materials, to help our customers achieve sustainability goals while meeting safety requirements for pharmaceutical packaging.10. How Do I Get a Quote?

Simply provide us with the drug type, package size, material requirements, design needs, etc. and our team will quickly provide a detailed quote based on your needs.11. Do You Provide Samples?

Yes, we provide sample service. You can choose free samples (only for the first time cooperation) or paid samples, and the sample production usually takes 5-7 working days.12. How to Ensure Anti-counterfeiting Function of Packaging?

We can integrate a variety of anti-counterfeiting technologies, such as QR codes, laser anti-counterfeiting labels, holographic patterns, etc., to help you protect your brand and consumers’ rights and interests, and to ensure the authenticity and safety of your medicines.

Contact Us for Your Needs

We're happy to help!

Not sure what you need? Contact our packaging experts who will help you find the best custom pharmaceutical packaging solutions for your brand.

+86-13827303202[email protected]Wenli Industrial Zone of Chaoshan road Anbu,Chaoan District, Chaozhou city, Guangdong Province