Innovative Solutions for Custom Healthcare Packaging

Your Trusted Custom Healthcare Packaging Manufacturer

The market for custom food pouches is growing rapidly as consumers focus on food safety and the environment.Meishida is committed to combining innovation with freshness, whether you’re launching an artisanal coffee, premium pet food, or organic snack, by combining high-barrier laminate construction, eco-friendly materials, and up to 10 colors of vibrant printing that will make you stand out on crowded shelves.

Our End-to-End Healthcare Packaging Innovation Partner

Diversified Healthcare Packaging Bag Types

Stand Up Pouch

Stand Up Pouch Shaped Pouch

Shaped Pouch Three Side Seal Pouch

Three Side Seal Pouch Side Seal Bag

Side Seal Bag Eight Side Seal Pouch

Eight Side Seal Pouch Roll Film

Roll FilmWant to Get the Best Selling Packaging? Contact Meishida Now!

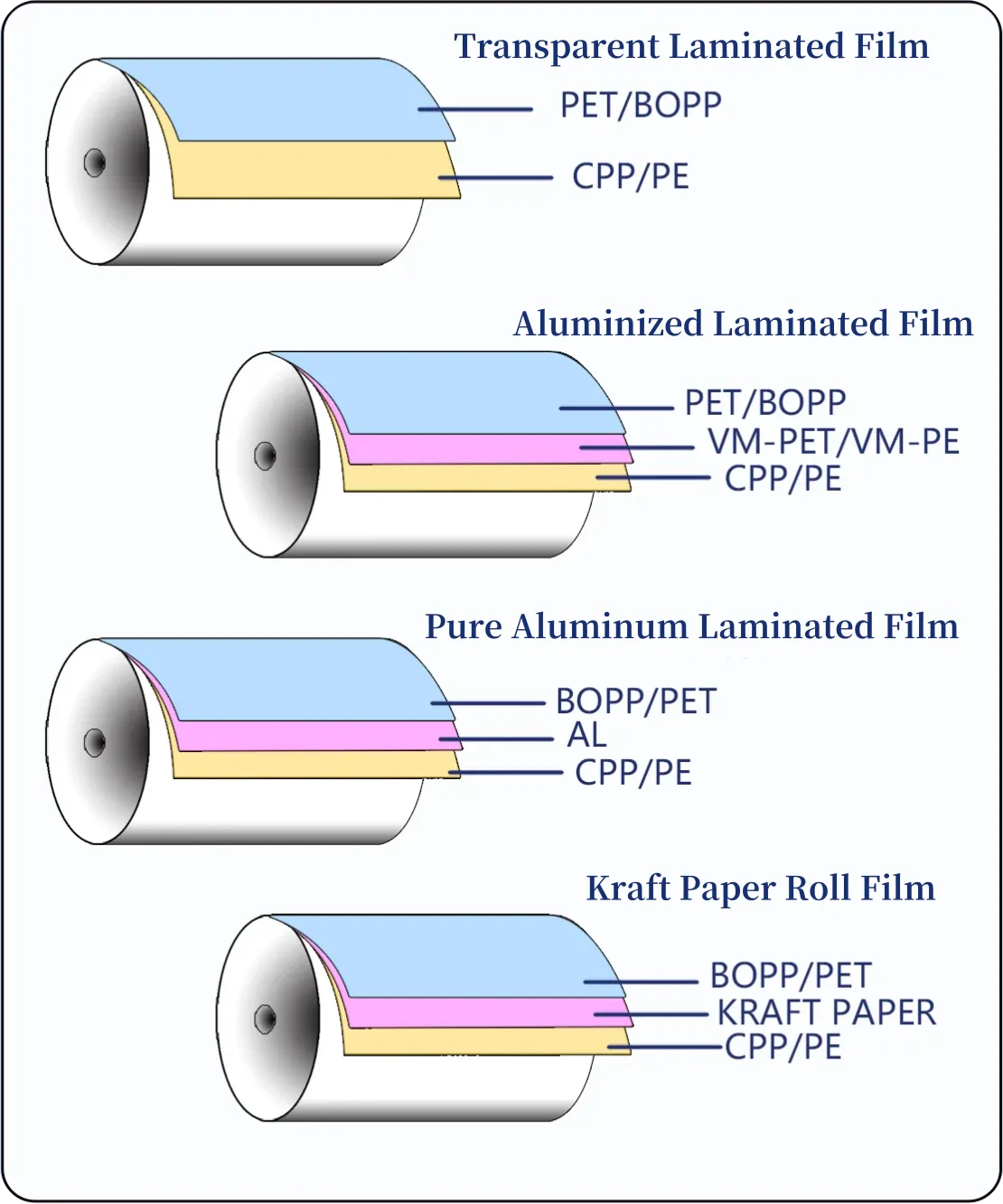

Commen Structures

PET/AL/PE, BOPP/AL/PE are common types of material structures that are more resistant to freezing and impact, with the PA layer providing good puncture resistance.

Please don’t worry about not knowing the laminated structure, we will choose the suitable laminated structure for your product.

Green Packaging, Leading the New Trend of Future Health Care Products

Against the backdrop of increasingly stringent environmental regulations, we are committed to developing and promoting recyclable and biodegradable healthcare packaging solutions. Our environmental strategy includes:

- Application of Recyclable Materials: Preferred materials such as PET and aluminum foil are used to achieve efficient recycling of packaging materials.

- Biodegradable Innovation: Introducing bio-based materials to reduce plastic pollution, in line with the global green development trend.

- Environmental Protection Certification: All products have passed international environmental protection certification, helping customers to enhance the green image of their brands.

Answers to Frequently Asked Questions about Custom Health Care Packaging

- 1.How to Choose the Suitable Packaging Material for My Healthcare Product?

For different healthcare products (e.g. liquid, powder, solid and topical products), we will recommend the most suitable packaging material and lamination structure according to the product characteristics, preservation environment and market requirements to ensure product quality and safety.

- 2.What Is The Production Lead Time For Custom Health Care Packaging?From design confirmation to production delivery, our overall cycle time is usually 4-6 weeks. For urgent orders, we also provide expedited services to ensure that your time-sensitive needs are met without sacrificing quality.

- 3.Does Your Packaging Comply with International Quality Standards and Environmental Regulations?All of our products comply with international quality standards such as GMP, ISO, FDA, etc. We also use environmentally friendly materials to ensure that our products meet the latest regulatory requirements when circulating in the global market.

- 4.Can you Support Small Batch Customization and Subsequent Batch Expansion?Whether it is small batch customization at the trial marketing stage or large scale production expansion, we have the flexible production capacity and professional technical support to meet the needs at different stages.

- 5.How does Customized Packaging Respond to Future Market Changes and Regulatory Updates?We pay close attention to the global healthcare market dynamics and regulatory trends, and continue to optimize the design and application of materials to ensure that your packaging solutions are always at the forefront of the industry.

- 6.How to Ensure the Safety of Packaging during Logistics and Storage?Using advanced lamination technology and high-barrier materials, our packaging designs focus on compression, tear and moisture resistance, effectively reducing the risk of product damage during transportation and storage.