Pharmaceutical Packaging Solutions

Your Pharmaceutical Packaging Supplier

Meishida is a creative and trusted one-stop provider of pharmaceutical packaging solutions. We set the standard for pill, liquid and device pouch packaging while working with our network of industry customers and partners to deliver quality products to patients.

Our advanced pharmaceutical and medical stand-up pouches, flat pouches, and laminated web films are designed to protect goods from moisture, oxygen, light, odor, chemicals, and contamination while extending shelf life.

In addition, our foil pouches are an easy way to seal pharmaceutical flexible packaging, making your goods more consumer-friendly for patients who need to reseal them for reuse.

Our End-to-End Pharmaceutical Packaging Innovation Partner

Pharmaceutical Packaging Solutions for Different Packaging Types

Stand Up Pouch

Stand Up Pouch Shaped Pouch

Shaped Pouch Three Side Seal Pouch

Three Side Seal Pouch Side Seal Bag

Side Seal Bag Eight Side Seal Pouch

Eight Side Seal Pouch Roll Film

Roll FilmWant to Get the Best Selling Pharmaceutical Packaging Solutions?

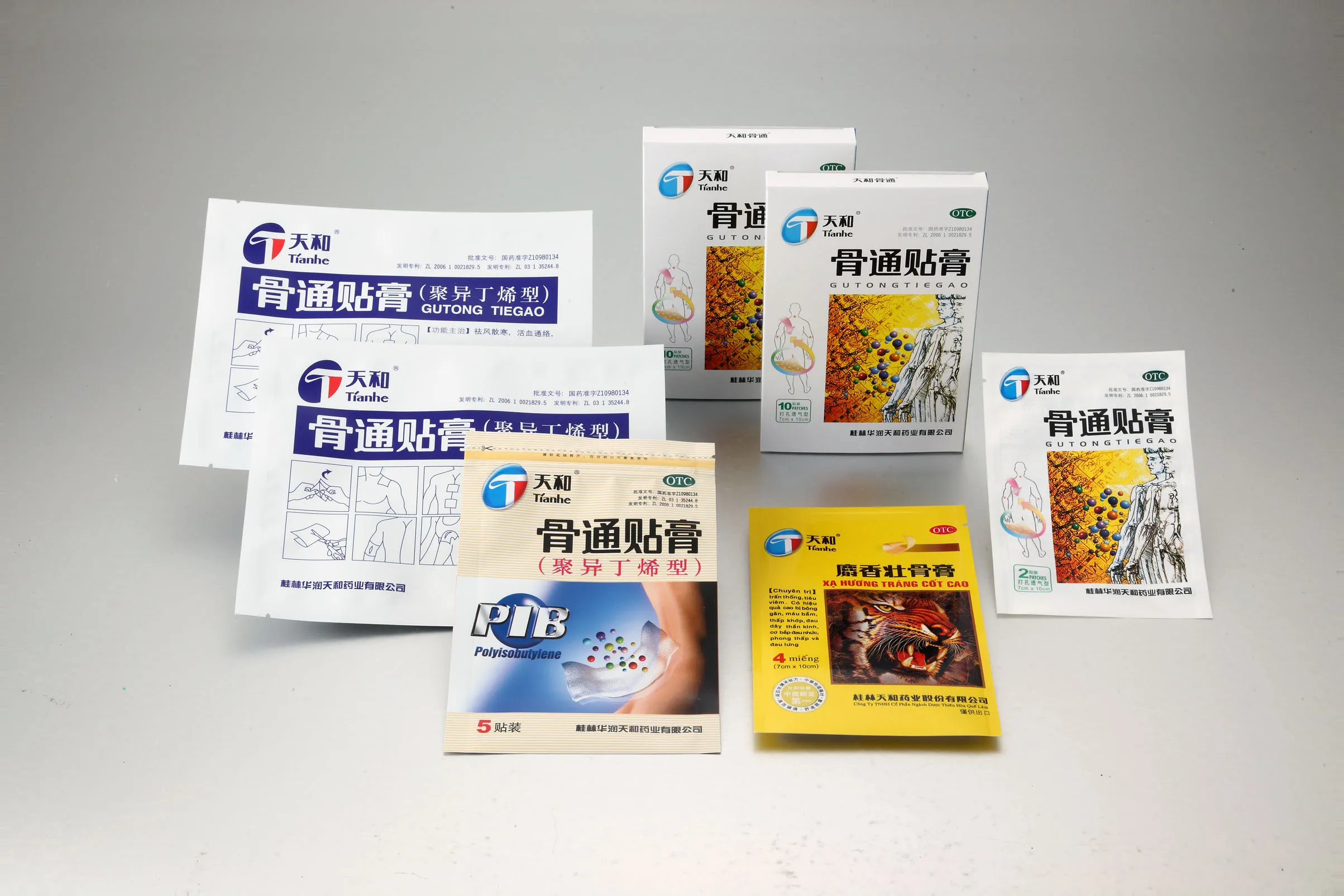

Customized Pharmaceutical Bag Designs

Capsule Packaging

Tablet Packaging

Granule Packaging

Ointment Packaging

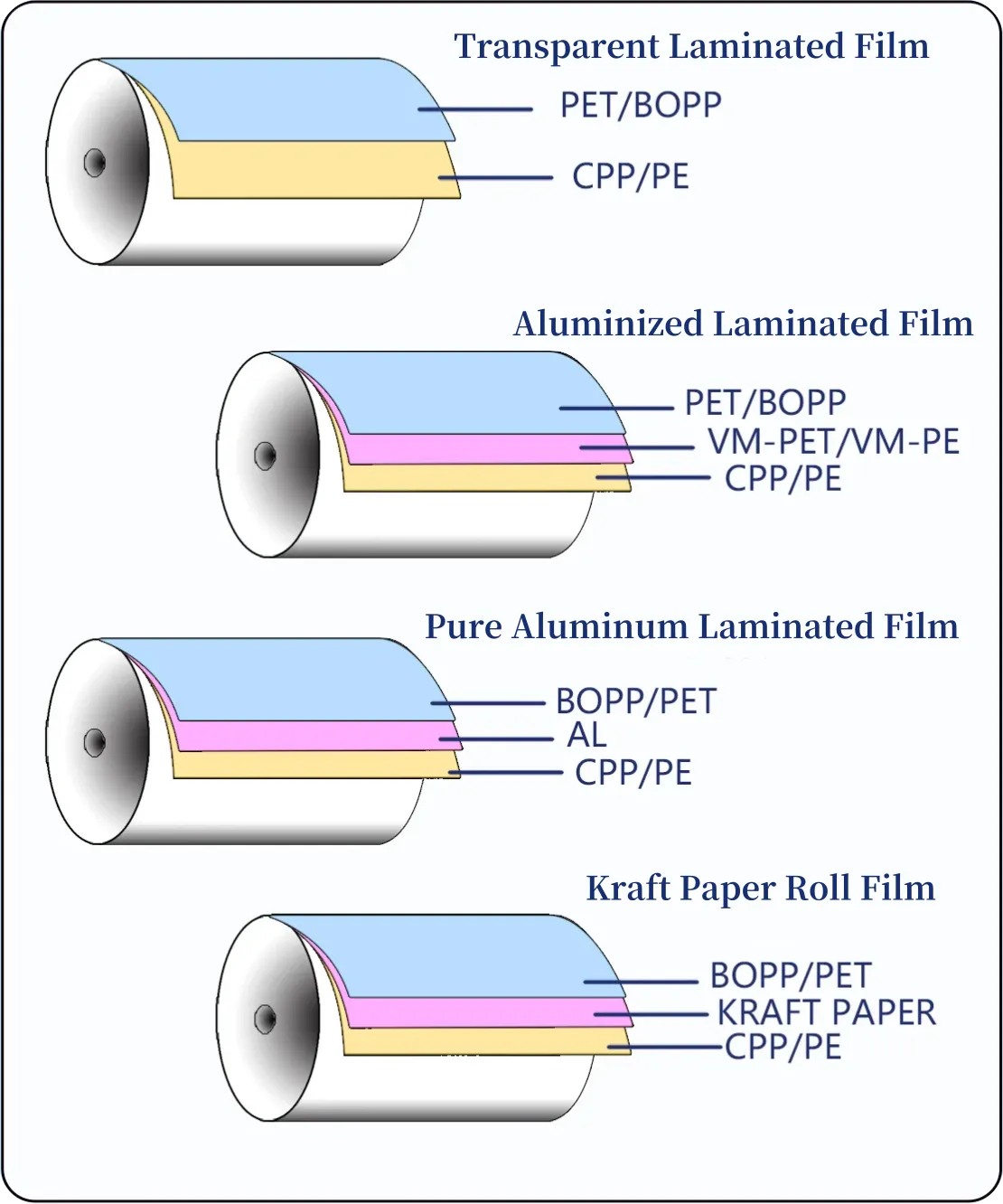

Precise Laminated Construction to Protect Pharmaceuticals

PET/AL/PE, BOPP/AL/PE, PET/PE/CPP are suitable for pharmaceutical packaging with high protection requirements, providing excellent barrier properties.

Please don’t worry about not knowing the laminated structure, we will choose the suitable laminated structure for your product.

Eco-friendly Pharmaceutical Packaging Solutions

Innovative, Recyclable and Biodegradable

Meishida is committed to providing sustainable, customized pharmaceutical packaging solutions that help companies meet green standards and reduce environmental impact. Our packaging not only provides efficient protection, but also complies with global environmental regulations and promotes the greening of the pharmaceutical industry.

Sustainable Packaging Features:

- Recyclable Materials: All packaging materials can be reused, reducing waste of resources

- Biodegradable Plastics: Degradable plastics are used to reduce plastic pollution

- Certification of Eco-friendly: Comply with ISO, FDA and other international environmental certifications.

Common Custom Pharmaceutical Packaging FAQ - Professional Answers to Your Concerns

- 1. How to Choose the Right Pharmaceutical Packaging Material?Choosing the right pharmaceutical packaging material should not only consider the type of drug, but also pay attention to the storage conditions, transportation environment and regulatory requirements. Common pharmaceutical packaging materials include aluminum foil, PET, PE, PP, etc. These materials have different barrier properties, moisture resistance and mechanical strength. We provide professional packaging consulting services to recommend the most suitable customized pharmaceutical packaging materials according to the chemical properties, shelf life and storage environment of the pharmaceutical products to ensure the long-term stability and market competitiveness of the products.

- 2. What is the Lead Time for Customized Pharmaceutical Packaging?Our customized pharmaceutical packaging services usually have a lead time of 4-6 weeks from design to delivery. We understand the pharmaceutical industry’s strict time requirements, so we are able to flexibly adjust the lead time according to your needs. For urgent orders, our production team is able to speed up the process and ensure that the quality of the packaging is undamaged to ensure on-time delivery.

- 3. Does Your Packaging Comply with GMP (Good Manufacturing Practice) Standards?Yes, all of our packaging solutions adhere to strict GMP standards and are quality certified for the global pharmaceutical industry, including ISO 9001, FDA and CE certification. We use high standard manufacturing processes and quality inspection systems to ensure that every batch of product complies with international drug safety regulations. We also provide transparent quality reports to our customers to enhance your trust.

- 4. Can Custom Pharmaceutical Packaging support small batch production?Yes, we support small batch production, which is especially suitable for the trial marketing stage of new drugs or testing for market feedback. We understand our customers’ need for flexibility in the early stage of market expansion, so we offer small batch customization services to help you test your products in the market with low risk and low cost. At the same time, our production facilities and supply chain management systems ensure consistent, high-quality packaging, even for small orders.

- 5. Can Custom Packaging Accommodate Future Regulatory Changes?As regulations in the global pharmaceutical industry continue to change, our customized packaging solutions remain highly flexible to adapt to new regulations. Whether it is FDA, EU or other regional pharmaceutical packaging regulations, we are able to provide packaging materials and design solutions that meet the latest requirements. We are committed to helping our customers increase the market value and competitiveness of their products while adhering to compliance.

- 6. How can I Ensure that the Customized Packaging Will Not Be Damaged During the Logistics Process?Our packaging design not only focuses on aesthetics and compliance, but also takes into full consideration the challenges that may be encountered during transportation and storage. We use tear-resistant, compression-resistant, and high-barrier laminates to ensure that the packaging remains intact in various logistical environments. We customize the appropriate form of crush-resistant packaging according to the different needs of pharmaceuticals, thus reducing the risk of damage during transportation.

- 7. Can Your Packaging Solutions Support Global Delivery?We provide customized pharmaceutical packaging for global customers and have a strong international logistics support network. Whether it’s North America, Europe, or the Asia-Pacific region, we are able to ensure fast and safe delivery to the destination. In addition, our packaging meets international export standards, helping you to pass through customs and quarantine procedures in each country.